Highly sensitive <5000IP-1>metal detector

- group name

- Metal detector machine

- Min Order

- 1 piece

- brand name

- Syndar

- model

- 5000IP-1

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T

- update time

- Thu, 03 Jun 2021 17:28:05 GMT

Paramtents

Conveyor length 1,000~2,000mm

Conveying height of metal detectors machine 500~1,500mm (±&-20mm)

Conveying speed fixed(22m/min) and variable speed (maximum 44m/min

Metal Detection standard rejection system alarm shutdown, audible and visual alarm

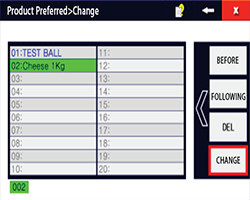

Preset number 100 products can be saved

Packging & Delivery

-

Min Order1 piece

Briefing

A detector that has higher sensitivity than ordinary metal detectors and can detect various impurities.

Detailed

With Highly sensitive <5000IP-1>metal detector, you can:

Advantages of Highly sensitive <5000IP-1>metal detector

Highly sensitive <5000IP-1> metal detector is SYNDAR's new online food metal detector. This metal detection system can select the required requirements according to specifications. It has higher sensitivity than ordinary metal detectors and a more rigorous detection process....

Safeline metal detector problems:

●Up to 100 kinds of products are available for a variety of different settings, easy to operate, see the safeline metal detector manual for details.

●Metal detector conveyor machine additional option to install an external output printer detection history

●The latest version when the software is upgraded via USB and touch screen

Specification | 2010 | 2015 | 2020 | 2025 | 2030 | 2510 | 2515 |

2520

|

2525 | 2530 |

3010

|

3015

|

3020 |

3025

|

3030 | |

Tunnel size | width | 200 | 250 |

300

|

||||||||||||

height | 100 | 150 | 200 | 250 | 300 | 100 | 150 |

200

|

250 | 300 |

100

|

150

|

200 |

250

|

300 | |

Channel size | width | 150 | 200 | 250 | ||||||||||||

height | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | |

Detection sensitivity | Iron | 0.5 | 0.5 | 0.8 | 0.8 | 1 | 0.5 | 0.8 | 0.8 | 1 | 1 | 0.5 | 0.8 | 0.8 | 1 | 1.2 |

stainless steel | 0.8 | 1 | 1 | 1 | 1.2 | 0.8 | 1 | 1 | 1.5 | 1.5 | 0.8 | 1 | 1.2 | 1.5 | 1.5 | |

Specification | 3510 | 3515 | 3520 | 3525 | 3530 | 4010 | 4015 |

4020

|

4025 | 4030 |

4510

|

4515

|

4520 |

4525

|

4530 | |

Tunnel size | width | 350 | 400 | 450 | ||||||||||||

height | 100 | 150 | 200 | 250 | 300 | 100 | 150 | 200 | 250 | 300 | 100 | 150 | 200 | 250 | 300 | |

Channel size | width | 300 | 350 | 400 | ||||||||||||

height | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | |

Detection sensitivity | Iron | 0.5 | 0.8 | 1 | 1 | 1.2 | 0.8 | 0.8 | 1 | 1 | 1.5 | 0.8 | 0.8 | 1 | 1.2 | 1.5 |

stainless steel | 0.8 | 1 | 1.2 | 1.5 | 1.5 | 1 | 1.2 | 1.5 | 1.5 | 2 | 1 | 1.2 | 1.5 | 1.5 | 2 | |

Specification | 5010 | 5015 | 5020 | 5025 | 5030 | 5510 | 5515 | 5520 | 5525 | 5530 | 6010 | 6015 | SD5306020 | SD5306025 | SD5306030 | |

Tunnel size | width | 500 | 550 | 600 | ||||||||||||

height | 100 | 150 | 200 | 250 | 300 | 100 | 150 | 200 | 250 | 300 | 100 | 150 | 200 | 250 | 300 | |

Channel size | width | 450 | 500 | 550 | ||||||||||||

height | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | 70 | 120 | 170 | 220 | 270 | |

Detection sensitivity | Iron | 0.8 | 0.8 | 1 | 1.2 | 1.5 | 0.8 | 0.8 | 1 | 1.5 | 1.5 | 0.8 | 0.8 | 1.2 | 1.5 | 1.5 |

stainless steel | 1 | 1.2 | 1.5 | 1.5 | 2 | 1 | 1.2 | 1.5 | 2 | 2 | 1 | 1.2 | 1.5 | 2 | 2 | |

|

Conveyor length

|

1,000~2,000mm

|

||

|

Conveying height

|

500~1,500mm(±&-20mm)

|

||

|

transfer speed

|

Fixed (22m/min) and variable speed (maximum 44m/min)

|

||

Standard rejection system | Alarm shutdown, audible and visual alarm (selectable rejection device) | ||

Preset number | Can save 100 products | ||

|

Output

|

Relay (5A)/1A 1B 2EA, DC24V, AC220V current 0.2A

|

||

power supply | Single phase (110~220V) and three phases (220 to 380V, etc.), free cycle (50Hz or 60Hz) and fuse (3A) | ||

Operating temperature | 0°C to 50°C (recommended to use the machine under normal conditions) | ||

Features of Glass X-ray inspection:

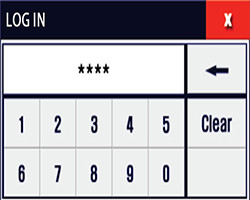

The metal detector for food factory sets up passwords suitable for different levels of authority (users, management and engineers) for different positions and different permissions

The metal detector in food industry can be integrated with conveyor belt systems to provide metal detector food production solutions.

The metal detector food grade enters the automatic setting mode, and the machine automatically sets the best sensitivity for the product being detected.

Applications

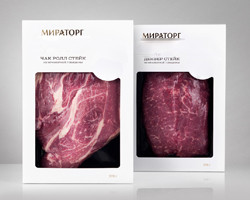

The metal detector food safety industry detects metal impurities mixed in products to improve safety and reduce hazards. For example: fresh vegetables, steak.

The metal detector for food industry can also detect metals in daily necessities, such as toiletries

SYNDAR food metal detector manufacturer can detect whether there are iron, stainless steel, copper, aluminum and other materials in industrial molds;

This series of detectors can also detect whether other metals are contained in coffee beans and other beverages.