Metal plastic container type X-ray inspection

- group name

- x ray inspection equipment

- Min Order

- 1 piece

- brand name

- Syndar

- model

- SD-X-5000,SD-X-7000

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T

- update time

- Fri, 23 Oct 2020 15:48:06 GMT

Paramtents

software Intellisense® Softwore

x ray inspection system Windows XP

in line x ray inspection power supply 100~240VAC, 50/60Hz

Detector type linear scan

x ray metal inspection display 15''LCD

Packging & Delivery

-

Min Order1 piece

Briefing

X-Ray output: 150kVp/7.5mA

Pixel size: 0.4mm

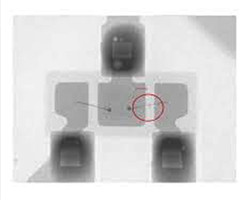

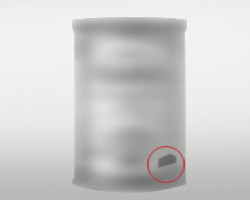

The X-ray inspection system can detect items in metal or plastic containers.

Pixel size: 0.4mm

The X-ray inspection system can detect items in metal or plastic containers.

Detailed

Metal plastic container type X-ray inspection, you can:

Metal plastic container type X-ray inspection advantages:

Metal plastic container type X-ray inspection is SYNDAR's new online x ray inspection food. It can detect metal or plastic filled food or beverages. In addition to detecting contaminated foreign objects, it can also detect the integrity of the product.

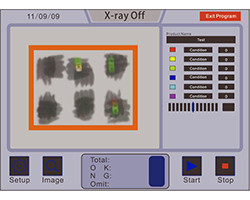

●x ray inspection systems food industry intuitive operating system.

●x ray inspection services has a professional service team to cooperate with users to provide solutions.

●x ray inspection system manufacturers provide free inspection and free maintenance.

●X-ray source has low power consumption, strong penetrating power and long service life, which can improve your company's stable sales and prevent foreign matter disputes in advance (litigation)

|

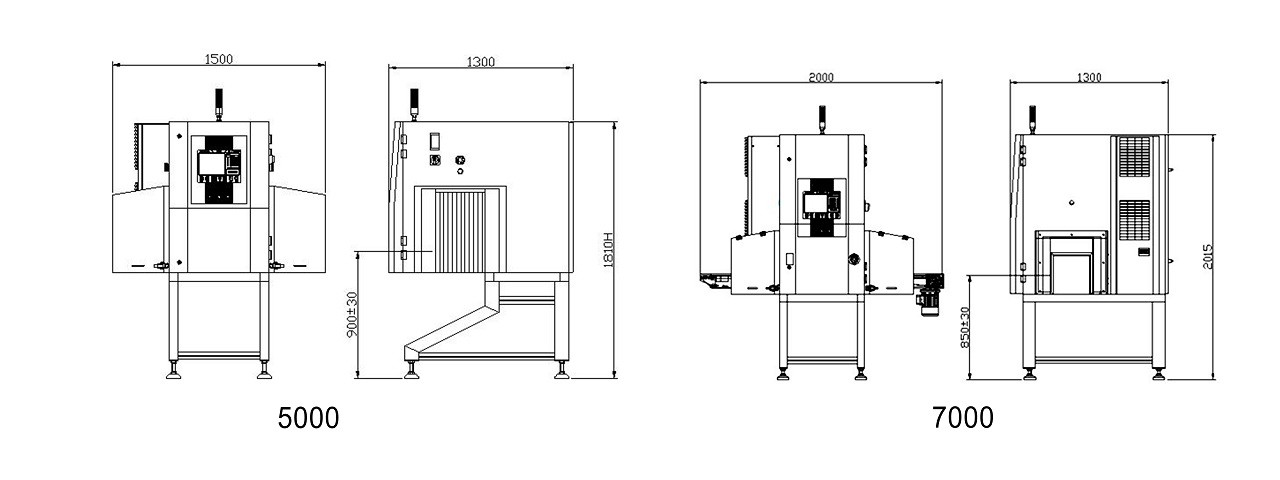

Model

|

SD-X-5000

|

SD-X-7000

|

|

Conveying bandwidth (mm)

|

85

|

200

|

|

Conveyor height (mm)

|

900±30

|

900±30

|

|

Conveyor speed (m/min)

|

10~100

|

10~100

|

X-Ray output | 150kVp/7.5mA | 150kVp/7.5mA |

X-Ray leaked | <1uSv/h | <1uSv/h |

Detector type | Linear scan | Linear scan |

Pixel size | 0.4mm | 0.4mm |

Display | 15'' touch screen | 15'' touch screen |

Software | Intellisense® Softwore | Intellisense® Softwore |

operating system | Windows XP | Windows XP |

power supply | 100~240VAC,50/60Hz | 100~240VAC,50/60Hz |

Operating environment | Ambient temperature: 50~35°/humidity: 30~85%RH (no condensation) | Ambient temperature: 50~35°/humidity: 30~85%RH (no condensation) |

Weight (Kg) | 455 | 650 |

Size (mm) | 1500×1300×1810 | 2000×1300×2060 |

Product size chart

Features of Glass X-ray inspection:

x ray food inspection equipment Multi-view X light source works simultaneously, covering the entire area to the greatest extent, avoiding blind spots and improving the possibility of detection.

Conventional packaging applications include plastic containers, cartons/cartons, aluminum foil bags, sack bags, plastic pallets, packaging bags and more.

The highest detection accuracy of x ray machine for food is as follows: lead: 0.2mm, SUS: 0.28mm, stone glass: 1.2mm

Applications

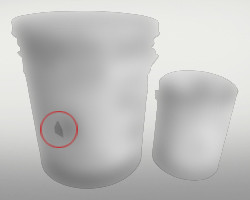

The X-ray inspection system for packaging products can detect contaminants at high speed and high accuracy, and can be used to detect aluminum cans of milk powder.

x ray canned food inspection whether there are defects in the product, such as damage, packaging defects, missing packages, etc.

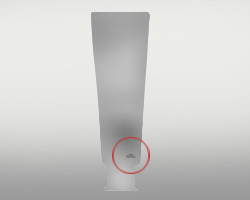

The x ray machine food safety inspection system can also detect non-food items, such as metal filling paint.

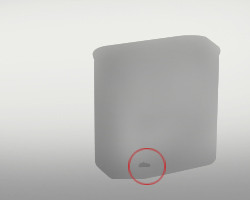

Can detect contaminants in plastic containers. Such as: toothpaste.