How to Make the Operating Results of the Checkweigher More Accurate?

time2022/03/08

- This article will introduce some things to pay attention to when operating the checkweigher equipment to make the results of the checkweigher more accurate.

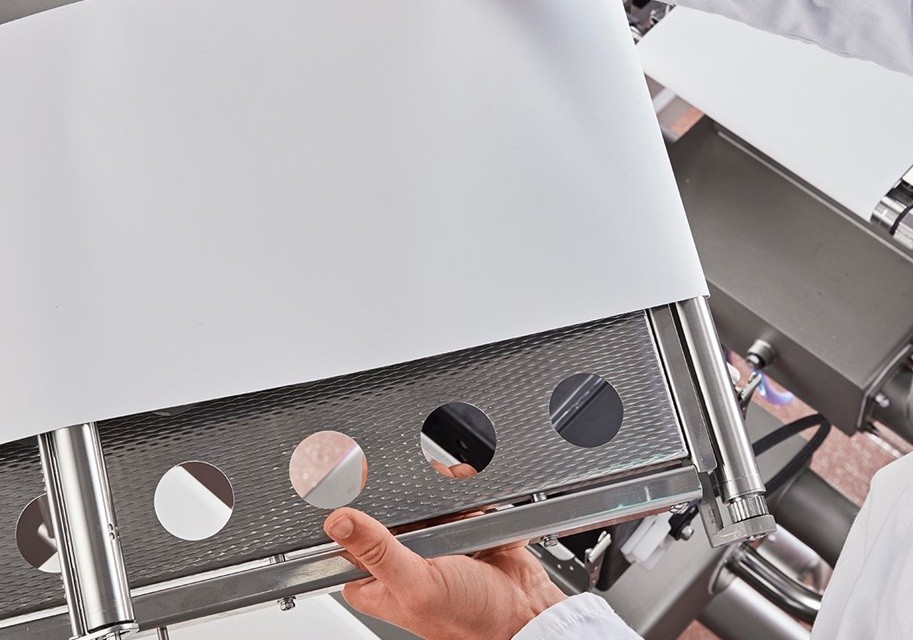

The checkweigher is a very precise weight testing equipment. If we can follow these precautions during use, we can greatly reduce the probability of the checkweigher failure and make its measurement results more accurate.

1. The protective grounding layer is reserved (for example, the communication cable of the sensor cannot be processed in parallel with the weak current power plug or control line (for example, the sensor power line and the weak current power plug and control line do not need to be placed in the same pipe). If they must be processed in a parallel place, then the interval between them should be kept above 50CM, and the power supply should be fixed with a metal hose.

2. As far as possible, choose structural components with automatic and precise positioning (calibration) functions, such as ball and rolling bearings, joint bearings, and precise positioning screws.

3. The level adjustment includes two aspects. On the one hand, the installation of a single sensor requires a level to adjust the level. On the other hand, the installation plane of the mounting base for multiple sensors can be adjusted to a level surface (with a level gauge) if possible.

Especially in weighing equipment with more than three sensors, this point should be paid more attention, because the key purpose of doing so is to take a load of each sensor roughly the same. The load position of each checkweigher is clear, and everyone should try to reduce the transverse force, additional bending distance, and torque when using it.

4. When using the sensing element, pay attention to preventing obvious heat conduction.

5. The mounting surface of the base of the sensor should be leveled, clean, free of oil, glue, etc. The mounting base itself needs to have sufficient compressive strength and rigidity, and generally requires high compressive strength and bending rigidity.

6. Although the checkweigher has a certain load capacity, it should be avoided that the sensor is overweight during the entire installation process of the weighing equipment. Please note that even if it is short-term overweight, it is likely to cause permanent damage to the sensor.

7. In any case, the power plug and control wire should be twisted tightly, horizontally at 50 pm. If you need to increase the sensor power cord, you should choose a specially manufactured sealed cable connection line terminal.

If you want to know more about checkweigher equipment after reading the above, please continue to pay attention to our news.

As a professional supplier of checkweighing and inspection systems, we are constantly optimizing and adjusting solutions based on customer needs. We have a professional production department and a complete management system and carry out strict quality inspections on all aspects of our products. Our thoughtful one-stop service has also won praise and trust from many customers. If you are interested in our checkweigher, please contact us immediately!