What Are the Applications and Functions of the Dynamic Checkweigher?

time2021/12/28

- In this article, Syndar shared with you the specific applications and functions of the dynamic checkweigher, which allows you to better apply the dynamic checkweigher in the assembly line.

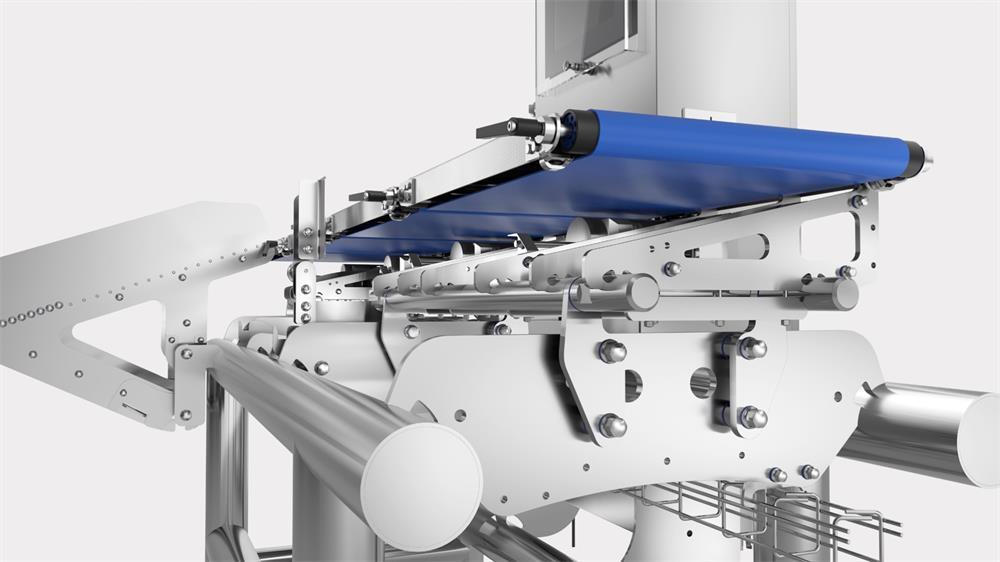

The dynamic checkweigher can detect the weight of each product 100% and divide the products into two or more groups by weight. It is dynamic weighing equipment on the production line, which can be embedded in the factory production line to automatically weigh, sort, and check the weight of each measured product, and can identify unqualified products according to the preset standard weight comparison, and automatically eliminate products of abnormal quality. The following introduces the main application and function of the dynamic checkweigher.

Main application

Detect the net content of the product, eliminate overweight and underweight products; detect missing parts of the product, such as whether there is a lack of instructions in the medicine box; product classification, such as chicken drumsticks by weight. The dynamic checkweigher is a kind of online weighing machine equipment, which can monitor the product quality problems on the production line of the production line, and is favored by many manufacturing enterprises.

Function

1. Net content inspection: single product (bag, box, package, bottle, can, etc.) weight inspection;

2. Package inspection: FCL/bag/package products are less or missed inspection;

3. Parts and accessories detection: product manuals, accessories, and accessories missed installation and leakage detection;

4. Weight sorting: according to the different weight ranges set in advance, the sorting section can automatically sort products of different weight specifications to the corresponding weight grade area;

5. Eliminate substandard products: mainly to help manufacturers detect unqualified products such as net product content, missing product packaging, and product containing metal impurities, and finally automatically remove them.

Features

1. Strong practicability: 7/10 inch high color, high-resolution man-machine interface, simple and friendly operation, easy to use. A variety of product preset functions, change product parameters in place with one button.

2. High stability: self-developed weighing recognition algorithm, automatic dynamic zero tracking and anti-vibration algorithm, weighing data recognition faster and more stable.

3. Convenient connection: easy to integrate into the user assembly line, production data report function, quickly understand the production status, with data storage, output, and printing functions.

4. Simple and stable: modular structure, easy to disassemble, easy to maintain, and easy to clean.

5. High compatibility: customized according to the actual needs of customers, and can be integrated with metal detectors, barcode scanners, labeling machines, automatic inkjet printers, automatic carton sealing machines, inspection machines, etc.

The assembly line dynamic checkweigher can find product quality problems at the front or end of the production line, which can help companies save manpower, improve efficiency, and achieve customer satisfaction. The dynamic checkweigher manufactured by Syndar is fully equipped with these functions and features and has an irreplaceable advantage in the assembly line.

As a professional weighing and inspection system supplier, Syndar has accumulated many years of experience in this field. We strictly control the quality of our products to ensure that every component can undergo strict quality inspection. Our products are sold well to companies all over the world and have been well received by many customers. At the same time, we are also committed to meeting the diverse needs of users. If you want to buy our online checkweigher, please contact us immediately!