10 Reasons for You to Choose Automatic Checkweigher

time2021/12/22

- In this article, Syndar specifically shared 10 reasons for choosing automatic checkweighers, so that everyone can better understand the characteristics and advantages of automatic checkweighers.

The online checkweigher measures the weight of the product during the conveying process of the product and compares the measured weight with the preset range, and the controller sends an instruction to reject products with unqualified weights, or reject products with different weight ranges. The product is distributed to the designated area.

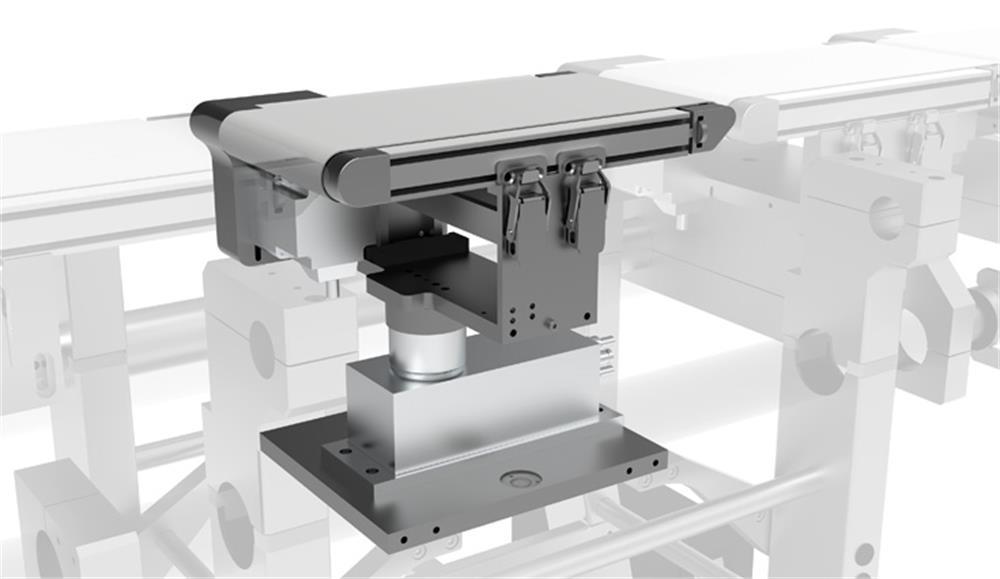

The online checkweigher is generally produced by a weighing conveyor, a controller, and an in-out conveyor. Among them, the weighing conveyor completes the collection of the weight signal and sends the weight signal to the controller for processing. The feed conveyor mainly increases the speed to ensure that there is sufficient spacing between products. The discharge conveyor is used to transport the tested products out of the weighing area.

The working process of the online checkweigher is as follows: the weighing preparation product enters the feeding conveyor, and the speed setting of the feeding conveyor is generally determined by the distance between the products and the required speed. The purpose is to ensure that only one product can be on the weighing platform during the work process of the checkweigher.

When the product enters the weighing conveyor, the system recognizes that the product to be tested enters the weighing area according to external signals, such as photoelectric switch signals, or internal level signals. According to the operating speed of the weighing conveyor and the length of the conveyor, or according to the level signal, the system can determine the time when the product leaves the weighing conveyor.

From the product entering the weighing platform to leaving the weighing platform, the load cell will detect the signal shown in the figure below, and the controller selects the signal in the stable agricultural area for processing, and the weight of the product can be obtained. Sorting process After the controller obtains the weight signal of the product, the system will compare with the preset weight range to sort the product.

In addition to the feedback function, the checkweigher can also provide a wealth of report functions, such as the packaging quantity per zone, total volume per zone, qualified quantity, qualified total, average, standard deviation, total quantity, and total accumulation. The online checkweigher can be applied to various industries, as various industries such as food, medicine, chemical industry, beverage, plastic, rubber, and so on. The followings are the specific advantages of using automatic checkweighers.

Help you effectively control costs

Customers often use checkweighers for the purpose of complying with relevant regulations. In fact, using checkweighers can effectively reduce waste, improve detection accuracy, and help you improve the efficiency of your production line. The investment cost of an automatic checkweigher may be profitable in just a few months, weeks or even days.

Reject high fines and ensure 100% weight inspection

By using an online checkweigher, you can ensure that all products meet regulatory requirements and industry standards. As an important part of quality control and process management, 100% weight inspection can also provide documents and process requirements that meet the strict needs of the market.

Feedback control to ensure effective filling volume

The feedback control system is used to prevent overweight and underweight products by setting control points in the filling equipment and adjusting the filling volume accordingly. The automatic checkweigher can directly control the filling equipment or complete automatic feedback control through the existing network system of the factory.

Save costs and increase product profits

An automatic checkweigher with good accuracy settings can minimize product weight deviation, reduce waste, and ensure that more products can be produced without changing the number of raw materials used.

Comprehensively promote process improvement and efficiency

The automatic checkweigher provides real-time monitoring of the production process, including production data statistics and SPC trends, which can be used to improve production and production efficiency factors.

Improve product quality to meet the strict production process of customers

The use of automatic checkweighers as a tool to reduce product weight tolerance and repeatability of the inspection process has become an important factor in ensuring product quality and meeting customer requirements as always.

Save labor

In routine applications, static balances are used to perform spot checks on products. In comparison, the use of dynamic online weighing can reduce potential sampling errors and long-term labor costs.

Reduce false rejection rate, avoid rework and discard

A good production process requires an accurate and well-maintained checkweigher, and at the same time, it requires as few products as possible to be rejected. Strict weight deviation requirements require continuous improvement of the production quality process, thereby reducing product waste and rework. The false rejection rate is controlled and reduced, the accuracy of the automatic checkweigher is more accurate, and the weight zone setting is more reasonable.

Ensure that the interests of customers are not affected

The automatic checkweigher and its application will not jeopardize the customer's contract because of the mode of transportation and product application, etc., to ensure satisfactory products and delivery dates.

Improve production line efficiency

The efficiency of the entire line of equipment has been improved after the three aspects of "effectiveness, performance, and quality" have been improved. 100% product weight monitoring can provide valuable data support for the production process and reduce unnecessary downtime. Strict product weight deviation requirements can be used to reduce overweight and underweight by using automatic checkweighers to obtain higher production efficiency.

As a professional weighing and inspection system supplier, Syndar has accumulated many years of experience in automatic checkweighing scales. We strictly control the quality of our products to ensure that every component can undergo strict quality inspection. Our products are sold well to companies all over the world and have been well received by many customers. At the same time, we are also committed to meeting the diverse needs of users. If you want to buy our online checkweigher, or get solutions for automatic checkweighers, please contact us immediately!