Which Sensor is Better for Automatic Checkweigher?

time2021/11/03

- The load cell is a key factor that affects the accuracy of the automatic checkweigher, so the choice of which type of sensor is particularly important. Today, let’s talk about which sensor is better for automatic checkweigher.

Currently, automatic checkweighers have been widely used in many manufacturing industries. Whether it is for the inspection of food, daily chemical, pharmaceutical, petrochemical industries, or for the inspection of batteries and auto parts, companies use checkweighers as a key means of inspecting product quality and quantity. Currently, there are two main types of load cells used in automatic checkweighers: strain resistance sensors and electromagnetic compensation sensors. The following is a detailed introduction to the applications and functions of these two sensors.

When the checkweigher uses an electromagnetic compensation weighing sensor (that is, the sensor form used by the electronic balance), if the repeatability of the checkweigher is poor, there will be high precision and low repeatability. The final result is that the dynamic accuracy is very poor, and it is difficult to adjust the dynamic accuracy through parameters.

When the checkweigher selects the strain resistance sensor (that is, the sensor used in industrial scales, automatic quantitative scales and batching control, etc.), if the repeatability of the checkweigher is very high, low precision and high repeatability will occur. However, finally, by adjusting the dynamic and static ratio coefficients, the dynamic accuracy of the checkweigher can reach a very high level.

The core component of the checkweigher is the load cell. Currently, two types of load cells are commonly used internationally: strain resistance sensors and electromagnetic compensation sensors.

The working principle of the electromagnetic compensation weighing sensor is the principle of electric conversion: when the current passes through the wire between the two poles of the permanent magnet, the electromagnetic force is generated by the action of the electromagnetic field.

In order to balance this system, it is necessary to add some auxiliary devices, such as a scale that needs to place the object to be measured and a displacement sensor that distinguishes the position of the wire in the magnetic field.

In addition, a current regulator and a measuring loop to measure the current are required. When no load is applied, a certain current controlled by the current regulator flows in the wire, so that the two pointers of the indicator at the same horizontal position remain stationary, and the system reaches a balanced state. At this time, the current indicated on the measuring instrument corresponds to the zero point, that is, the zero point of the balance.

Electromagnetic compensation weighing sensors are widely used in electronic balances in the laboratory and are characterized by high sensor accuracy, generally 0.001%. Taking into account the influence of the conveyor on the weighing platform, the overall static weighing accuracy of the general weighing platform is 0.01% of the range.

An electromagnetic balance process is needed inside the sensor, the weighing stability time is longer, and the dynamic response time is slower. Therefore, a check weigher using an electromagnetic compensation type load cell cannot break through the dynamic accuracy bottleneck of 400 pieces/minute and a positive/negative deviation of 300mg.

The strain resistance load cell is made up of four resistance strain gauges attached to metal aluminum or stainless steel elastomer to form a Wheatstone bridge. When the sensor is under force, its shape changes. This forces the resistance values of the four strain gauges pasted on the sensor to change accordingly, in which the resistance value under squeeze becomes smaller, and the resistance value under tension becomes larger. Through the Wheatstone bridge measurement circuit, the resistance change can be measured more accurately, and the force can be converted.

Strain resistance load cells are commonly used in industrial scales and special weighing control in various industrial situations. They are characterized by being suitable for the harsh environment of industrial sites, with rapid dynamic response and a sensor accuracy of 0.01%. Taking into account the influence of the conveyor on the weighing platform, the overall static weighing accuracy of the general weighing platform is 0.03% of the range.

Different sensors have their specific advantages and limitations. In fact, we need to be clear that the factors that affect the dynamic accuracy of the checkweigher are not just the type of sensor used. For example, even if the accuracy of the load cell is very high, if the machine's own motor vibration, product vibration, and basic vibration cannot be overcome. Even if a very high-precision balance sensor is selected, the desired dynamic accuracy may not be achieved.

Factors that affect the dynamic accuracy of the checkweigher, in addition to the mechanical vibration of the machine itself, the length of the product, internal shaking of the product, and environmental factors will all affect the accuracy. Of course, being equipped with a high-precision load cell can certainly improve the accuracy of the equipment to a certain extent.

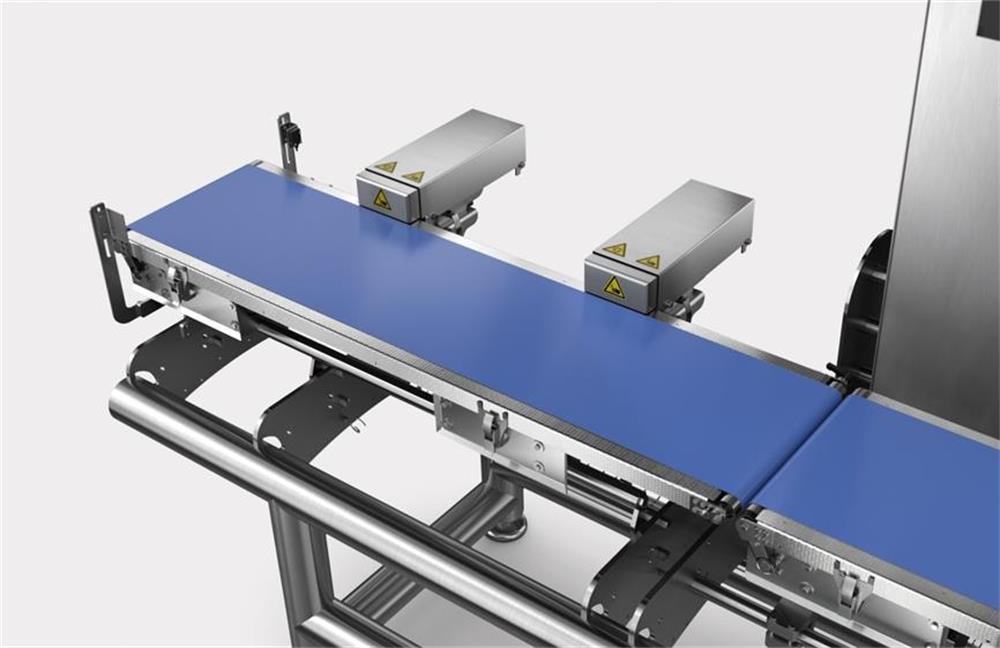

The automatic checkweigher manufactured by Syndar is suitable for the end-of-process inspection of the packaging line and provides a more economical solution for simple online checkweighing requirements. It has the characteristics of fast inspection speed, high measurement accuracy, and strong expansion performance. If you are interested in our products, you can directly search for relevant content on our website for further.

As a professional manufacturer of checkweighing and inspection systems, we have won praise and trust from many customers with our excellent technology and high-quality products. We have a standardized production team and can conduct a comprehensive quality inspection of the products. At the same time, we will also give top priority to customer needs, providing complete and effective solution technology and thoughtful one-stop service. If you are interested in our automatic checkweigher, please contact us immediately!