What is the Workflow of the Online Automatic Checkweigher?

time2021/10/22

- The online automatic checkweigher can detect the pass rate of the product weight and reject the products with unqualified weight. Let's learn about the workflow of the online automatic checkweigher.

The online checkweigher is a medium-low speed, high-precision online checkweighing equipment, which can be integrated with various packaging production lines and conveying systems. It is mainly used to check whether the product weight is qualified, whether there are missing parts in the package, or the product weight archive.

Online automatic checkweighing has gradually become an indispensable link in modern industrial production, especially in the production process of food and pharmaceutical industries.

The online checkweigher completes the measurement of the weight of the product during the transportation of the product and compares the measured weight with the preset range, and the controller sends an instruction to reject products with unqualified weights, or remove products with different weight ranges, and then deliver to the designated area.

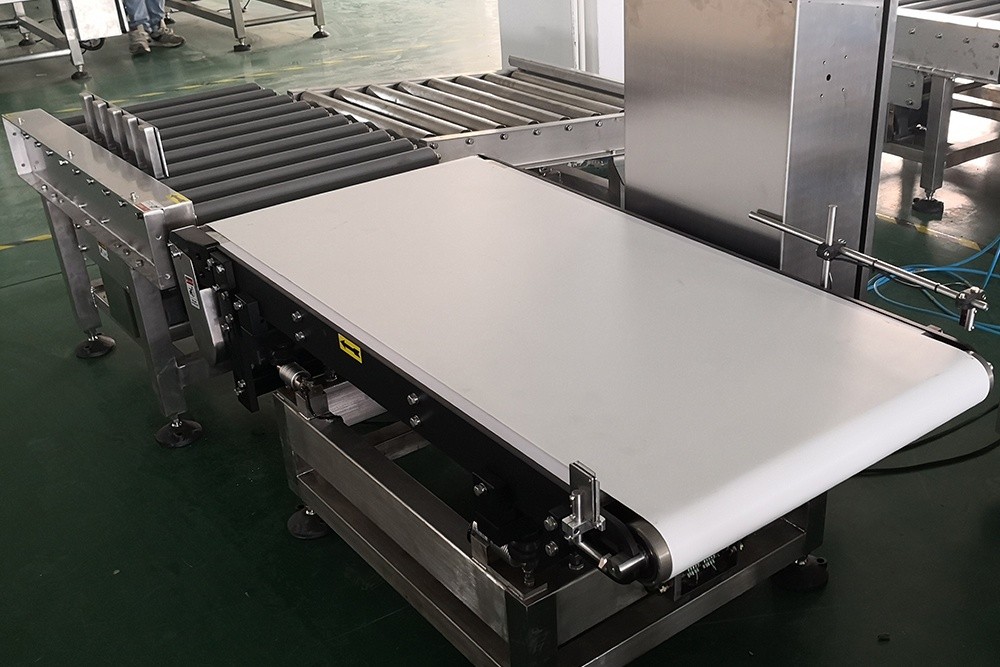

The online automatic checkweigher is generally produced by a weighing conveyor, a controller, and an in-out conveyor. Among them, the weighing conveyor completes the collection of the weight signal and sends the weight signal to the controller for processing.

The feed conveyor mainly increases the speed to ensure sufficient spacing between products. The discharge conveyor is used to transport the tested products out of the weighing area. The following is the specific workflow of the online checkweigher.

Weighing preparation

The product enters the feeding conveyor, and the speed setting of the feeding conveyor is generally determined by the distance between the products and the required speed. The purpose is to ensure that only one product is on the weighing platform during the work process of the checkweigher.

Weighing process

When the product enters the weighing conveyor, the system recognizes that the product to be tested enters the weighing area according to external signals, such as photoelectric switch signals, or internal level signals.

According to the operating speed of the weighing conveyor and the length of the conveyor, or according to the level signal, the system can determine the time when the product leaves the weighing conveyor.

From the product entering the weighing platform to leaving the weighing platform, the load cell will detect the signal shown in the figure below, and the controller selects the signal from the stable agricultural area for processing, and the weight of the product can be obtained.

Sorting process

After the controller obtains the weight signal of the product, the system will compare with the preset weight range and sort the products. The sorting type will be different according to the application. There are mainly the following types:

(1) Rejection of unqualified products

(2) Eliminate overweight and underweight separately, or transport to different places

(3) According to different weight ranges, divided into different weight categories

(4) Report feedback

Checkweighers have a weight signal feedback function. Usually, the average weight of a set number of products is fed back to the controller of the packaging/filling/canning machine, and the controller will dynamically adjust the feeding amount to make the average weight of the product closer to the target value.

In addition to the feedback function, the checkweigher can also provide a wealth of report functions, such as the packaging quantity per zone, total volume per zone, qualified quantity, qualified total, average, standard deviation, total quantity, and total accumulation.

The online automatic checkweigher can eliminate unqualified products to ensure that the weight of the products delivered meets the requirements. This helps ensure the interests of both consumers and production companies. Syndar can provide high-precision and high-quality checkweigher equipment, which can be used in various industries to ensure the pass rate of the production line.

As a professional manufacturer of checkweighing and inspection systems, we have won praise and trust from many customers with our excellent technology and high-quality products. We have a standardized production team and can conduct a comprehensive quality inspection of the products. At the same time, we will also give top priority to customer needs, providing complete and effective solution technology and thoughtful one-stop service. If you are interested in our automatic checkweigher, please contact us immediately!