How to Ensure the Accuracy of the Checkweigher?

time2021/09/08

- The checkweigher is a very precise checkweighing equipment, and the requirements for accuracy are very high. This article will specifically introduce measures to ensure the accuracy of the checkweigher.

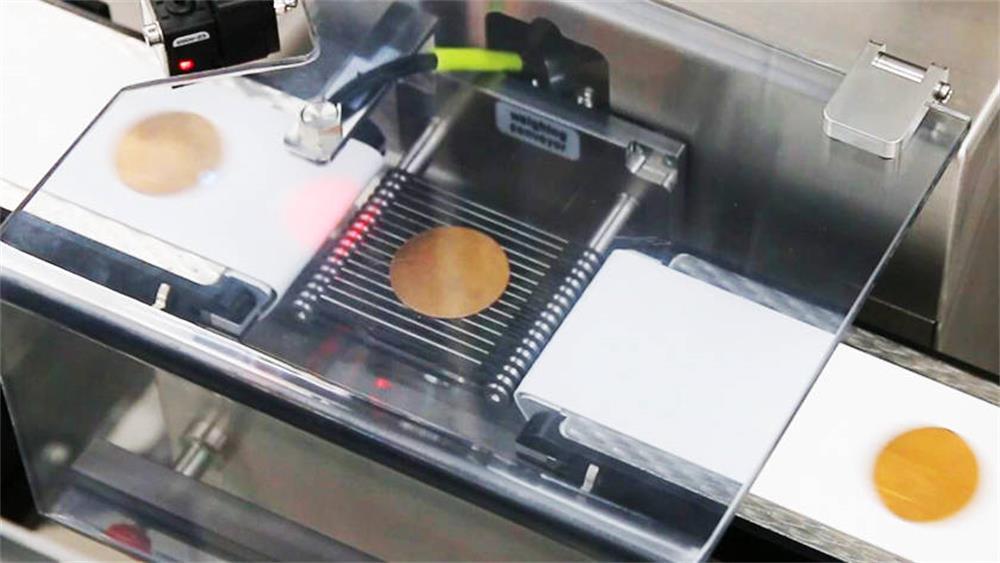

Many production lines will choose checkweighers to check whether the product quality is qualified, so we need to find ways to ensure the accuracy of the equipment during the use of checkweighers. The following are the factors that affect the accuracy and the specific measures to ensure accuracy.

Factors affecting accuracy

(1) Air flow

For example, the fan, air conditioner, and wind in the workshop all have an impact on the accuracy of the checkweigher.

(2) Ground vibration

Because of the high noise in the workshop, the frequent operation of the machine causes ground vibration, which will affect the accuracy of the checkweigher.

(3) Temperature

High temperature, low temperature, humidity, and extreme ambient temperature will affect the accuracy of the checkweigher. In general, the suitable working environment for the checkweigher is -5℃~40℃, relative humidity: 95%.

(4) Electrostatic induction

Charged objects or dust will generate static electricity when they approach metal objects, causing interference or even damage to the sensitive checkweigher.

(5) Radio frequency interference

Various radio frequencies can interfere with the checkweigher, making the checkweigher unable to feedback data in time.

(6) There are omissions in the product

For example, the packaging box is not tightly sealed, leading to omissions. This small phenomenon also has a certain impact on accuracy.

(7) Human use error

In the process of use, if there is a mistake due to human operation, it is easy to cause damage to the checkweigher sensor.

Measures to ensure accuracy

(1) Ensure the passing state of the detected object

Since the checkweigher is mainly used for weighing assembly-line products, the circulation state of the object has a greater impact on the accuracy of the dynamic checkweigher when weighing. Each product to be tested needs to maintain a sufficient distance to prevent the dynamic checkweigher from overlapping the weighing of the product. There is also the need to ensure the stability of the product assembly line surface. If the surface is unstable or uneven, the data measured by the checkweigher is also in error.

(2) Improve the measurement environment

Checkweighers are usually used to measure some more precise products. At this time, we must pay attention to the fact that under such accurate conditions, changes in the environment will have a big impact on the accuracy of the checkweigher. Therefore, it is necessary to ensure the stability of the surrounding environment to prevent radio interference

(3) Choose a suitable checkweigh sensor

The accuracy control of the checkweigher is mainly determined by the internal sensor. Sometimes the quality of the sensor directly affects the quality of the checkweigher. Therefore, it is necessary to select a suitable sensor to achieve more objective accuracy.

Choosing a high-quality checkweigher can reduce accuracy errors and reduce the probability of failure. Syndar is committed to providing customers with high-quality and high-precision checkweighers. If you want to obtain related services about checkweighers after reading the above content, please contact us.

As a professional manufacturer of checkweighing and inspection systems, we have won praise and trust from many customers with our leading production technology and experienced manufacturing team. We have a strict quality management department that conducts comprehensive quality inspections on all production links of the products. We will also provide thoughtful one-stop service according to customer needs. If you want to buy our checkweigher, please contact us immediately!