Daily Cleaning Steps and Precautions of Automatic Checkweighers

time2021/09/01

- Daily cleaning and maintenance of the automatic checkweigher can keep the equipment in good working condition. Let's learn about the daily cleaning steps and precautions of the automatic checkweigher.

The automatic checkweigher is an electronic device with high weighing accuracy and fast detection speed. It can store a variety of product parameters for easy editing and switch at any time. In order to ensure the good working performance of the automatic checkweigher, the following daily cleaning and some matters need to be paid attention to in the process.

Cleaning steps

1. Clean the weighing platform of the automatic checkweigher

After cutting off the power of the checkweigher machines, unplug the power cord. Soak the gauze and wring it dry, then dip a small amount of neutral cleaning fluid (such as alcohol), use it to clean the weighing pan, display filter, and other parts of the weighing body.

2. Level correction

Check whether the scale body of the automatic checkweigher is normal. If it is tilted, you need to adjust the feet of the scale so that the weighing platform is placed in the center position.

3. Clean the printer equipment

The automatic checkweigher equipped with a printer needs to cut off the power first, open the door on the right side of the scale body, hold the outside handle of the printer, and drag the printer out of the scale body. Press the reed on the front of the printer, loosen the print head, and gently wipe the print head with the special cleaning pen that comes with the scale accessory. After removing and scrubbing, cover the cap of the pen to prevent the cleaning fluid from evaporating in the pen.

Then wait for two minutes. After the cleaning liquid on the print head evaporates sufficiently, close the print head, push the printer back into the scale body, close the plastic door, power on the test, and do normal use after the print is clear.

4. Initialization

The automatic checkweigher has the functions of zero-point tracking and zero-clearing at power-on. The foreign matter on the weighing pan is cleaned up after power-on, ensuring that the scale is powered on when there is no wind around. If there is a small amount of weight display after starting up, you can press the reset button on the keyboard to restore the scale to the zero position.

Precautions

1. When cleaning and maintaining the checkweigher scales, be sure to cut off the power of the machine and operate it by professionally trained staff.

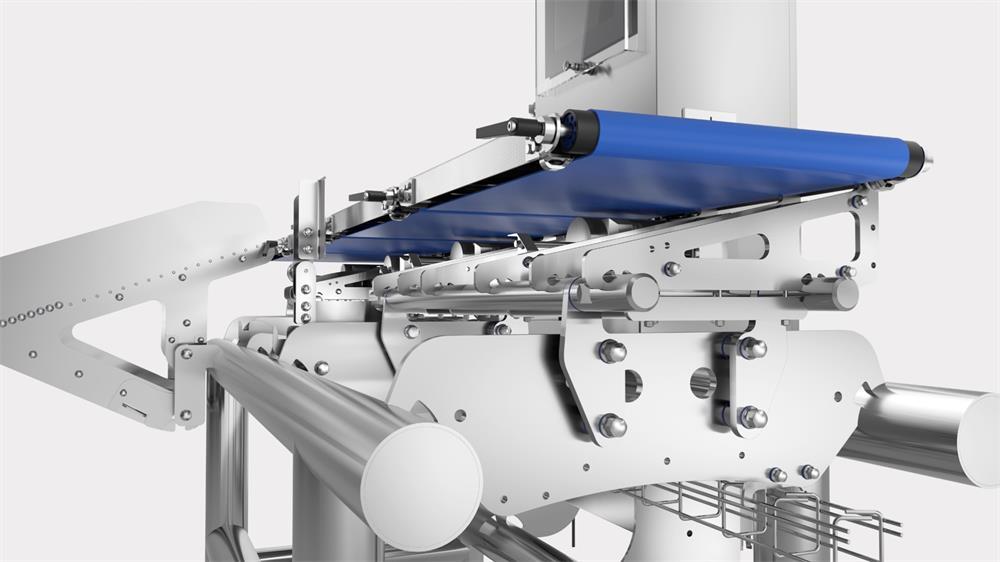

2. After using the checkweigher systems every day, the feeding belt, weighing belt, sorting belt, toggle lever, windshield, etc. should be cleaned in direct contact with the object under test.

4. Before each use of the automatic checkweigher, the flexibility of the three conveyor belts should be specially tested to prevent the material from being jammed, which may scratch or wear the belt.

4. According to the use environment of the automatic checkweigher, clean the equipment at regular intervals.

Checkweighers are widely used in food, electronics, pharmaceuticals, chemicals, hardware, and other industries. In order to ensure the normal operation of weight sorting machines and prolong their service life, routine maintenance work must be done. If you want to know more about the automatic checkweigher after reading the above, you can contact us for professional solutions.

As a professional manufacturer of checkweighing and inspection systems, we have won praise and trust from many customers with our leading production technology and experienced manufacturing team. We have a strict quality management department that conducts comprehensive quality inspections on all production links of the products. We will also provide thoughtful one-stop service according to customer needs. If you want to buy our checkweigher, please contact us immediately!