How to Test the Accuracy of the Checkweigher?

time2021/08/17

- To ensure that each batch of products can be accurately measured, the checkweigher needs to be tested for accuracy. This article will specifically introduce the method of testing the accuracy of the checkweigher.

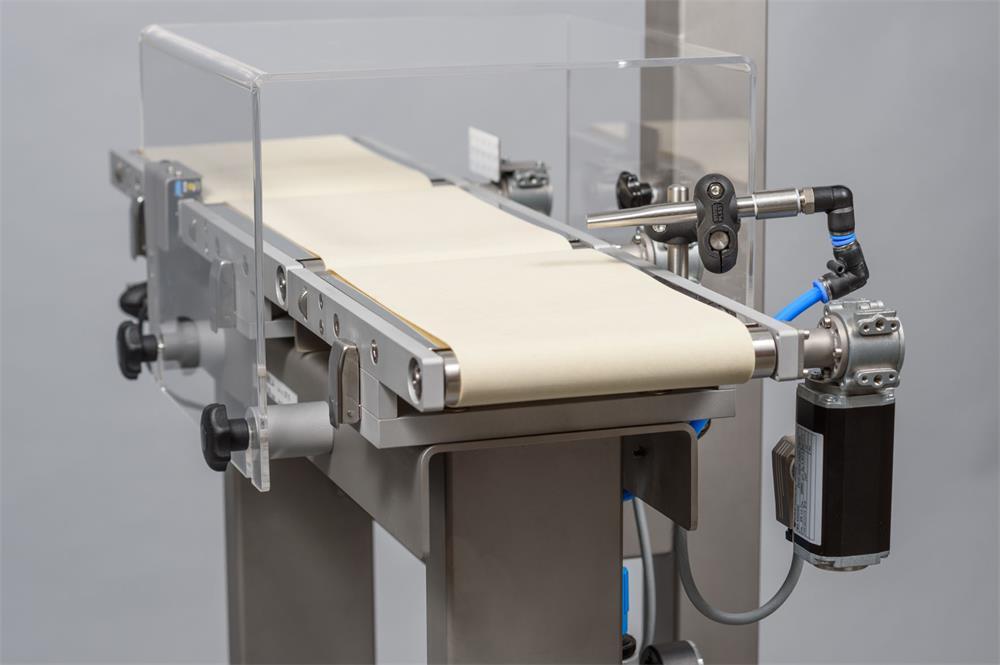

The checkweigher is a key piece of equipment on the automated production line. It has high precision, fast speed, and can store the weight of a single product and the total weight of each batch of products. However, in the process of using the checkweigher, if you want to ensure each batch of products can achieve an accurate measurement, then the accuracy test of the checkweigher is required. The following is the accuracy-test method of the checkweigher.

The first test is to pass the same product through the weight sorting machine 10 or 20 times to ensure that the direction of the product is consistent with your actual production direction during each pass.

1. Record each data. There are some checkweighers that can automatically record and calculate the standard deviation. If the weight sorting machine cannot be calculated automatically, you can use the STDEV formula in the Excel table to calculate.

2. After having the standard deviation, multiply it by 6 to get the unconfidence interval (a globally recognized method for calculating the uncertainty of dynamic check weighing).

3. For example, if the weight of your product is 200 g, then TNE(-T1) is 5% or 9g.

4. Now calculate a quarter of this 9g, which is 0.25 x 9g = 2.25g. This value is your repeatability limit.

5. If the unconfidence interval you calculated at first is greater than 2.25 g, then this checkweigher scale is unavailable under this setting.

Products of various types and weights that are checked on a checkweigher scale need to pass this test. And at regular intervals, we must repeat this test, and record and analyze the trend of each test. Observe how the test results change over time. Based on this trend, you can determine how often you need to perform such a test. These records and trend analysis are also effective proof of the property insurance risk assessment by users of checkweighers.

The second test is also carried out using the product under test. In addition, a calibrated static scale is also required. The resolution of the static scale needs to be the same as or higher than that of the ccheckweigher scale. This inspection needs to be performed before, after, and at the end of a batch. Similarly, this test can be used for trend analysis for further risk assessment.

1. Use an adjustment weight with a weight similar to the product to check whether the static scale can be weighed correctly.

2. Pass the product through the running checkweigher, and then place it on the static scale for weighing. Compare the weight value obtained on the checkweigher with the weight value obtained on the static scale. If the difference is greater than 1/5 of TNE, this checkweigher is not applicable. During batch processing, some checkweighers have a built-in weight check function, which will remove this product that is only used for testing and display its weight on the screen to facilitate testing.

3. Repeat this test at least once to check the repeatability of the checkweigher. For example, if the rated weight of our product is 200 g, the weight displayed on the checkweigher is 200.4 g, and the same product is taken to the static scale, and the weighing display is 199.7 g. The difference is 0.7 g. We know that the TNE of a 200 g product is 9 g. One-fifth is 1.8 g. 0.7g is less than the limit of 1.8g, the checkweigher can accurately measure and be used normally.

If you want to make the inspection accuracy of each batch of products reach the standard, you need to perform the above two tests and write these two tests into your standard workflow. If you want to learn more about the checkweigher after reading the above, you can contact us for professional information and related solutions.

As a professional supplier of checkweighing and inspection systems, we are constantly optimizing and adjusting solutions based on customer needs. We have a professional production department and a complete management system and carry out strict quality inspections on all aspects of our products. Our thoughtful one-stop service has also won praise and trust from many customers. If you are interested in our checkweigher, please contact us immediately!