5 Tips for Choosing a Checkweigher

time2021/06/18

- The checkweigher can guarantee the pass rate of product accuracy on the production line, and many factors need to be considered when choosing a checkweigher. This article will specifically introduce five tips for choosing the right checkweigher.

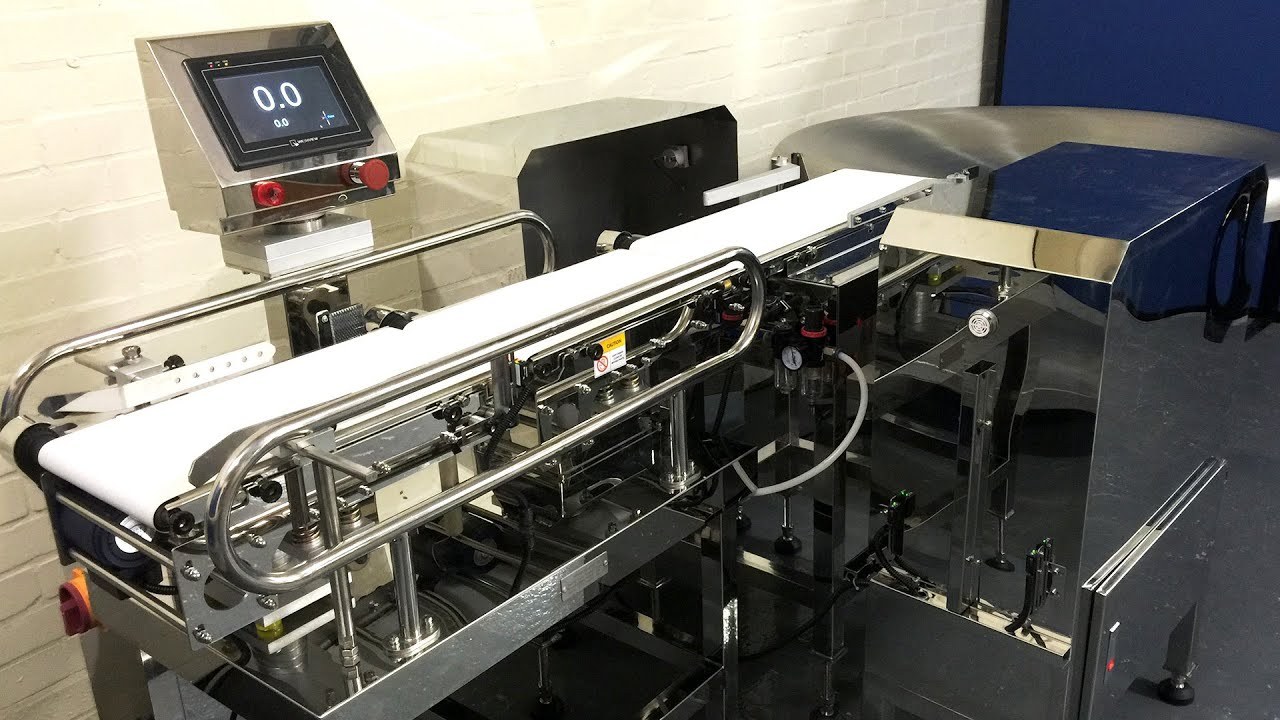

The checkweigher scale is suitable for testing products in the terminal process of the packaging assembly line and provides a more economical solution for realizing the efficiency of online checkweighing. Choosing the right checkweigher can ensure the realization of high accuracy and high-efficiency goals. Here are five tips for choosing the right checkweigher.

Machine Design

Look at the overall design of the checkweigher machines as it determines how operators will use the machine. The design also determines the overall reliability and accuracy of the weight measurements. An ideal checkweigher will have a strong, stable design that is mechanically stiff to ensure weight control.

Next, look at the frame material and construction. A welded frame can have stress points that impact accuracy. A non-welded frame may be less sanitary depending on the application. A checkweigher without hollow bodies on the frame helps prevent bacteria from forming during production.

Last, consider the overall footprint of the checkweigher. You need to consider whether your production line can put down the checkweigher of this size.

Checkweighers with a smaller or non-existent electrical cabinet are generally smaller and easier to add to the plant floor.

Controls and Ease of Use

Like other plant equipment, weight sorting machines should stand up to the varied conditions of a plant environment. Industrial-grade components should work accurately after repeated cleaning, maintenance, and general operating conditions over time.

In addition, the checkweigher should be easy to operate and control. For complete ease-of-use, choose a checkweigher with non-proprietary controls that will allow you to easily customize the checkweigher’s parameters for specific applications. Some checkweighers, including PLC-based checkweighers, make it easy to communicate with other systems in the plant and provide easily accessible data, which is important to optimizing operations.

Secure Connectivity and Data Collection

Security is a concern for every operation. While you want security, you still want a checkweigher that is easy to connect. By design, PLC-based controls eliminate the need for special coding and permissions since it communicates with Ethernet. A dedicated Ethernet connection will help keep checkweigher data and production information safe behind the firewall.

Data collection helps improve fill accuracy. Once a weight sorting machine is connected to a plant network, it has the ability to collect thousands, or even millions, of data points. You can use this information to find variances to further improve accuracy. Look for a checkweigher that allows you to download data in a useable format.

Easy Calibration

A checkweigher isn’t adding anything to your operations unless it’s calibrated. Here, checkweighers fall into two categories: strain gauge and Electro-Magnetic Force Restoration (EMFR) technology. Strain gauge weigh cell calibration is a manual, time-consuming process that can drift over time, requiring routine maintenance by a service technician.

EMFR technology, however, has no moving parts or components that can drift, eliminating practically all maintenance. Calibration is completed by machine operators or plants maintenance staff via software in a few minutes.

Weigh Cell Technology

Strain gauge and EMFR checkweighers also differ in accuracy and how well the checkweigher scale measures package weight in motion. Typically, to determine a baseline weight, you take several weights over time to determine an average weight.

Because there are no moving parts with EMFR, checkweighers that utilize this technology stabilize faster and can exponentially obtain more measurements in the same period of time.

While there are many other features to consider, but the above five factors will help you optimize your packaging line and overall operations over time. If you want to know more about the checkweigher after reviewing the above content, you can contact us for a detailed solution. At the same time, we produce various types of checkweighers with excellent performance, which can meet your real needs.

As a professional manufacturer of checkweighing and inspection systems, we have won praise and trust from many customers with our leading production technology and experienced manufacturing team. We have a strict quality management department that conducts comprehensive quality inspections on all production links of the products. We will also provide thoughtful one-stop service according to customer needs. If you want to buy our checkweigher, please contact us immediately!