Installation Method and Precautions of Automatic Checkweigher

time2021/05/27

- The invention of the checkweigher has brought great convenience to many industries, but there are still many people who don't know much about the installation of the checkweigher. This article will specifically introduce the installation method and precautions of the automatic checkweigher.

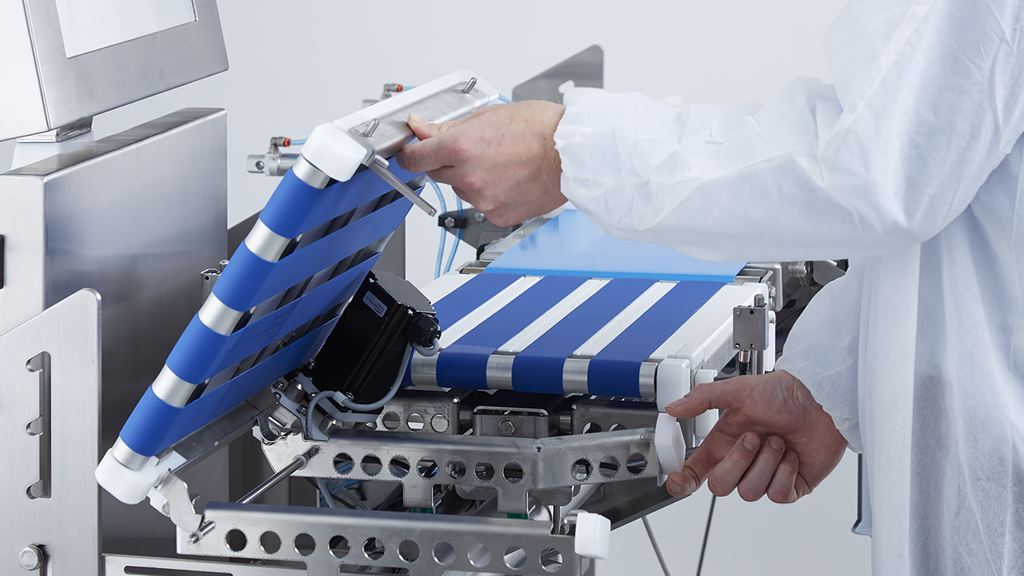

The automatic checkweigher is suitable for products that are inspected in the terminal process of the packaging assembly line, with fast inspection speed and high measurement accuracy. In order to ensure the normal operation of the automatic checkweigher, we need to pay attention to some matters when installing. The following are the installation method and precautions of the automatic checkweigher.

Installation steps

1. The packing box of the checkweigher scale is made of wood. The sensor protection device is in a reliable protection state during transportation. The protection device can be released after installation (the sensor pads have been removed, and there are removed accessories in the sealed bag).

2. Place the checkweigher at the place to be installed. Choose a location where there is no obvious vibration.

3. Put down the checkweigher machine carefully, and then remove the crate. Unpack the weighing conveyor belt.

4. Loosen the protective nut on the conveyor belt bracket. Avoid applying excessive pressure. It is forbidden to place any tools or other objects on the weighing conveyor belt, and do not let any objects fall on it, and install the sensor pad.

5. Align the checkweigher in the horizontal and left-right directions to ensure that the checkweigher scale is level.

6. The input conveyor belt and the output conveyor belt must be aligned and cannot touch the weighing conveyor belt, that is, the weighing conveyor belt must be able to move freely without touching other conveyor belts or objects.

7. Align all conveyor belts horizontally and vertically to ensure unimpeded product transmission.

Precautions

(1) When installing the sensor, use high-strength bolts to fasten the sensor.

(2) The load cell cannot exceed the set range to avoid damage to the load cell caused by overload.

(3) The load cell of the automatic checkweigher should be protected from the rain after installation.

(4) When two sensors are used, the two load-bearing points are required to be on the same horizontal plane, and the connection line of the load-bearing points of the two sensors is required to be parallel to the axis of the drum.

(5) The weighing sensor range of the automatic checkweigher should be greater than 120% of the weight of the material in the measuring section under the maximum flow rate of the belt scale. When multiple sensors are used, the scale of each sensor should be the same, and the performance indicators should be consistent.

If we do not install the checkweigher correctly, it may affect the accuracy of the product. If you want to know more information related to the checkweigher after reading the above content, you can contact us for more detailed solutions.

As a professional manufacturer of checkweighing and inspection systems, we have accumulated many years of production experience. We have a professional production team and a comprehensive quality control system, and we have strict quality control of the products. We can also provide thoughtful services and effective solutions according to customer needs. If you are interested in our checkweigher, please contact us immediately!