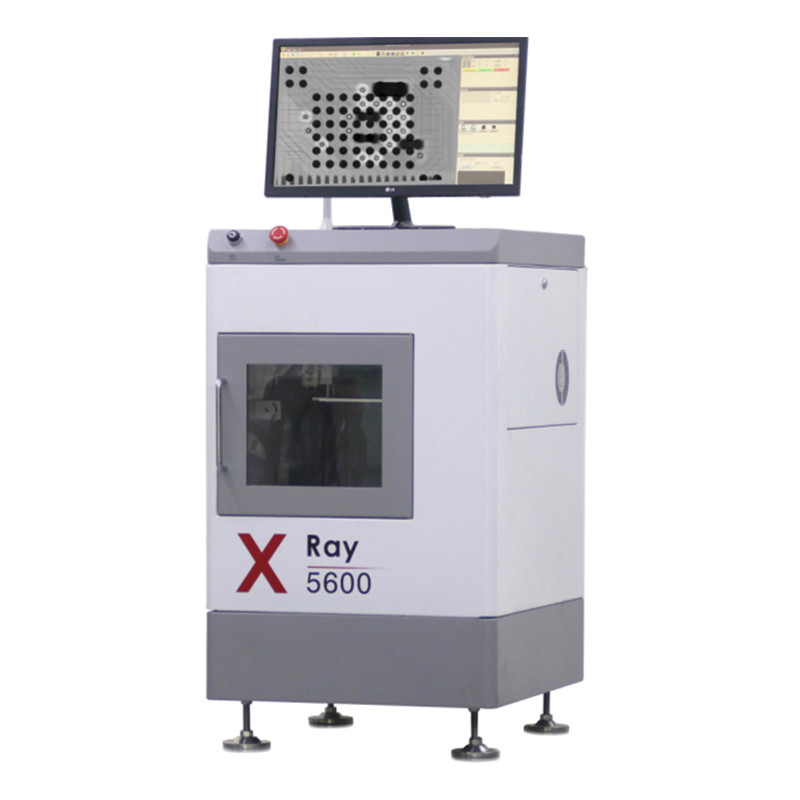

Advanced functions and powerful capabilities of X-ray foreign body detector technology

time2020/05/11

- The advanced X-ray technology is very powerful, which can not only perform impurity detection, but also improve the quality of packaging products.

Multi-function x ray inspection equipment can be extended application

The advanced X-ray technology is very powerful, which can not only perform impurity detection, but also improve the quality of packaging products. It is impractical if the operator is asked to manually inspect all the packaging to verify the integrity of the product or the product for sale inside the closed box. With high-resolution detectors, coupled with the fast processing capabilities of an efficient operating system, X-ray technology has the ability to ensure the integrity or integrity of the product. Therefore, with the enhancement of the modern x ray inspection system, especially with the increase in automation, which drives the increase in the speed of the packaging production line, tasks that could not be completed a few years ago are now easy. A more efficient operating system lays the foundation for smarter image analysis.

After years of development, X-ray technology has already possessed versatility and can ensure a higher level of product safety. For example, because of the limited functions of the Windows XP operating system software used, the functions of the previous x ray inspection system were very limited. Although the modern x ray inspection system continues to use the user-friendly Windows environment as the operating platform, it assigns image processing tasks to non-Windows-based systems, such as Linux systems. In this way, the processing speed is faster and more robust. In addition, the Linux system is a very advanced operating system, not only used on large servers, but also on the fastest supercomputers; therefore, with its own advantages, it can be perfectly suitable for packaging integrity inspection. Need to strengthen treatment.

The x ray inspection system performs imaging by measuring the amount of X-ray energy absorbed by the test product in the linear detector. The detector's diodes are usually 0.4mm or 0.8mm in size, arranged next to each other, scanning at a very high rate. The information received by each diode is called a pixel. These pixels have a gray value that is proportional to the density of the product being tested. When the pixels are arranged next to each other, a linear scan is obtained. Use the belt to transport the inspected product through the x ray inspection equipment, and then position the scanning lines side by side to obtain the X-ray image.